In the realm of industrial and wastewater treatment processes, the demand for effective solid-liquid separation solutions has led to the development of advanced technologies. One such innovation making waves in this domain is the dewatering screw press machine. This article explores the functionalities, applications, and benefits of dewatering screw presses, shedding light on their significance in achieving efficient and sustainable separation processes.

Understanding Dewatering Screw Presses

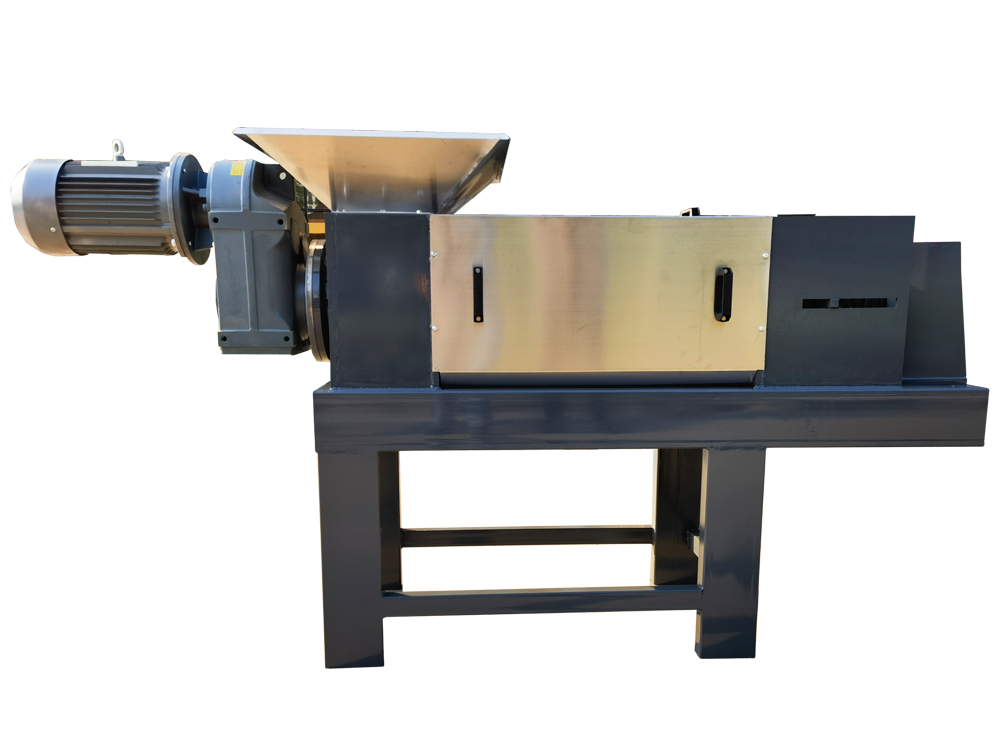

Dewatering screw presses are mechanical devices designed to efficiently separate solids from liquids, primarily in sludge and wastewater treatment applications. The core principle involves the use of a rotating screw within a cylindrical screen to compress and dewater the material, resulting in the extraction of water and the formation of compacted solids.

How It Works

Inlet Zone: The sludge or wastewater enters the dewatering screw press through an inlet, where the initial dewatering process begins.

Transportation Zone: The rotating screw moves the material along the length of the press, gradually applying pressure and facilitating the separation of water from solids.

Compression Zone: As the material moves further, the compression of solids increases, leading to enhanced dewatering and the formation of a dense cake.

Dewatered Output: The separated water is expelled, leaving behind a concentrated and dewatered solid cake that can be easily disposed of or further processed.

Applications of Dewatering Screw Presses

Dewatering screw presses find extensive applications across various industries and sectors due to their versatility and effectiveness. Some notable applications include:

Municipal Wastewater Treatment: Dewatering screw presses play a crucial role in treating municipal sludge, reducing the volume of waste and facilitating its safe disposal.

Industrial Processes: Industries generating sludge or wastewater with high solid content, such as food processing, mining, and chemical manufacturing, benefit from the efficient dewatering capabilities of screw presses.

Agricultural Residue Treatment: Dewatering screw presses are employed in the agricultural sector to manage organic residues, separating water from agricultural by-products for easier handling and disposal.

Advantages of Dewatering Screw Presses

High Efficiency: These machines offer a high level of dewatering efficiency, significantly reducing the moisture content of sludge or wastewater.

Compact Design: Dewatering screw presses are compact and require less space compared to other dewatering methods, making them suitable for both small and large-scale operations.

Energy Efficiency: The screw press design minimizes energy consumption, contributing to cost savings and environmental sustainability.

Low Maintenance: With fewer moving parts and a robust design, dewatering screw presses are known for their low maintenance requirements, ensuring continuous and reliable operation.

Conclusion

Dewatering screw presses represent a breakthrough in solid-liquid separation technology, offering a sustainable and efficient solution for managing sludge and wastewater. As industries and municipalities strive for more eco-friendly and cost-effective wastewater treatment processes, the adoption of dewatering screw presses is poised to grow, revolutionizing the way we approach solid-liquid separation challenges.

TEL:+86 15336363999

TEL:+86 15336363999

WeChat:gongchris1111

WeChat:gongchris1111

ADD:Fangzi District, Weifang City, Shandong Province, China

ADD:Fangzi District, Weifang City, Shandong Province, China